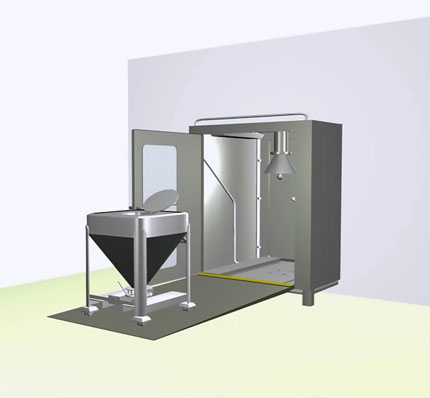

Container washing station

IBC Containers® washing stations have been designed to ensure a hygienic process with little effort for all types of containers. With minimum intervention of your operators, the IBC cleaning system will help you to save considerable time in the process of cleaning your bins.

Characteristics

|  |  |  |

| Step 1 - The container goes inside the washing station | Step 2 - Washing session: inside of the container | Step 3 - Washing session: outside of the container | Step 4 - The container goes out of the washing station by the other door |

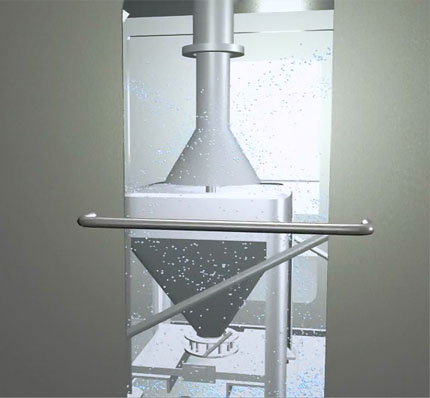

The washing of the inside of the container (IBC) is performed through a series of high pressure jets that follow an automatic process to ensure a total cleaning of all the surfaces. The power of the water jets enables to remove all substances from all surfaces and to prevent contamination.

The external cleaning is done via static nozzles strategically set to clean all the container surfaces but also the top and the drain valve.

Our container washing stations have been designed to fit the environment of your plant, but also to facilitate their maintenance. Thanks to its modular construction, installation and maintenance of your washing station will be carried out easily.

Washing system:

Our automatic washing station cleans, rinses and dries one container every 15 minutes. Two access zones are used to separate the clean side from the dirty side.

The container is introduced in the washing cabin through the contaminated area, or even called “dirty side” and is stabilized inside by positioning guides. The access door automatically locks when it is closed. Once the container cleaning process is finished, it is extracted through the clean area. In order to avoid the contamination of the both access areas, doors are inter-locked.

The PLC provides all data concerning the washing process. The washing cycles are programmable and can be pre-defined according to the products formerly used.

A washing cycle runs as follows: pre-washing of the internal and external part of the container, washing with soap and water, rinsing with pure water, drying with forced hot air and cooling with filtered air.

Need more information about our container washing machines? Visit our gallery below or contact us through our form.

Specifications

| STANDARD FEATURES | OPTIONS |

|---|---|

| Main washing nozzles located on the vertical axis, in the center of the container | Conveyor loading and unloading |

| Strategically positioning of spray nozzles to reach all external surfaces | Independent input and output doors (clean vs dirty area) |

| Horizontal opening of the door | Sliding automatic door |

| Secure door lock | Stainless steel manufacturing |

| Independent washing cycle of containers | Control of the temperature of washing and rinsing water |

| Detergent injection | Control system of the drying air temperature |

| Purified water rinsing | Draining and cooling system |

| Temperature controlled air-drying system | Purge of the pipes with filtered air |

| HEPA air-filtered system | Remote control panel |

| Electrical control cabinet |

The advantages of the container washing machine are the following:

• No retention area

• Soundproof cabinet

• Doors with tight seals and push locks

• Modular and automatic wash (configuration according to container size)

• Control panel with touchscreen

The utilities required to operate the washing cabin are electricity, compressed air, steam and water. In the case where the hot water is not available in your plant, IBC Containers® can provide an optional skid for production of controlled temperature water.